Lithium Forklift Batteries

ROYPOW specializes in developing lithium forklift batteries, boosting truck productivity with more shifts and less charging time. Our cells range from 24 to 80 volts, with a maximum of 350 volts, meeting the diverse needs for different scenarios from light-duty to heavy capacity. Certified by UL and CE standards and compliant with BCI and DIN battery size standards, we are your top choice for the US-based and European-targeted forklift market.

-

80V 690Ah Lithium Forklift Battery

80V 690Ah Lithium Forklift Battery

F80690K

-

48V 690Ah Lithium Forklift Battery

48V 690Ah Lithium Forklift Battery

F48690BD

-

36V 690Ah Lithium Forklift Battery

36V 690Ah Lithium Forklift Battery

F36690BC

-

24V 560Ah Lithium Forklift Battery

24V 560Ah Lithium Forklift Battery

F24560L

-

Explosion-Proof LiFePO4 Forklift Battery

Explosion-Proof LiFePO4 Forklift Battery

-

Anti-Freeze LiFePO4 Forklift Battery

Anti-Freeze LiFePO4 Forklift Battery

-

Forklift Battery Charger

Forklift Battery Charger

-

Forklift Battery Charger CHA20-110-200

Forklift Battery Charger CHA20-110-200

Benefits of Our Lithium-Ion Forklift Batteries

Retrofit your forklifts to Lithium-ion

> Higher charging/ discharging efficiency for stronger power output.

> Longer battery life with less downtime.

> Maintenance-free lithium system cuts costs throughout its lifespan.

> On-board fast charging without battery removal or replacement.

> No more watering, corrosion, or battery swapping.

-

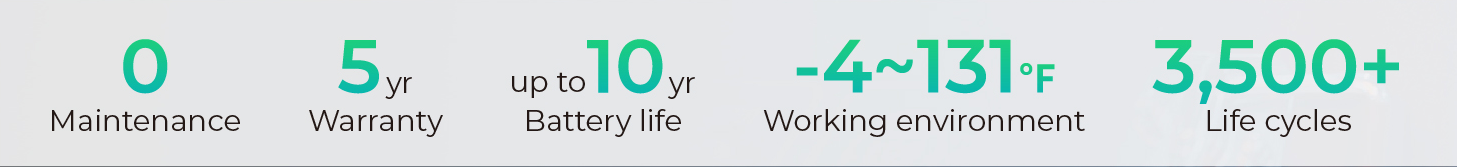

0

Maintenance -

5yr

Warranty -

up to10yr

Battery life -

-4~131′F

Working environment -

3,500+

Cycle life

Benefits

Upgrade your golf cart to lithium!

> More energy density, more stable and compact

> The cells are sealed units and require no water flling

> Upgrading conveniently and easy to replace and use

> 5 years warranty brings you a peace of mind

Why choose forklift batteries of ROYPOW?

Powered by lithium systems, our sealed forklift batteries are spill-proof and leak-proof, providing safer, smoother operations in industrial applications.Long Life & 5 Years Warranty

> 10 years design life, over 3 times longer than the lifetime of lead-acid batteries.

> More than 3500 times cycle life.

> 5 years warranty to brings you peace of mind.

Zero Maintenance

> Saving costs on labor and maintenance.

> No need to endure the acid spills, corrosion, sulfation or contamination.

> Saving downtime and improve productivity.

> No regular filling of distilled water.

Consistent Power

> Delivers consistent high performance power and battery voltage throughout the full charge.

> Maintains greater productivity, even toward the end of a shift.

> The flat discharge curve and high sustained voltage mean forklifts run faster on each charge, without getting sluggish.

Multi-shift Operation

> One lithium-ion battery can power one forklift for all multi shifts.

> Maximizing your operation productivity.

> Enables a large fleet working 24/7.

Build-In BMS

> Real-time monitoring and communication through CAN.

> All-time cell balancing and battery management.

> Remote diagnosing and upgrading software.

> Ensures the battery to provide peak performance.

Display unit

> Showing all critical battery functions in real-time.

> Showing key information about the battery, such as charge level, temperature and energy consumption.

> Showing remaining charging time and fault alarm.

NO Battery Exchange

> No risk of battery physical damage while exchanging.

> No safety issues, no exchange equipment needed.

> Saving further cost and improving safety.

Ultra Safe

> The LiFePO4 batteries have very high thermal and chemical stability.

> Multiple built-in protections, including over charge, over discharge, over heating and short circuit protection.

> The sealed unit don't release any emissions.

> Remote control automatic warnings when issues arise.

Ultimate solution for lithium-ion forklift batteries

Our electric forklift batteries have broad applications in warehouse and logistics centers, manufacturing factories, ports and shipping terminals, cold storage and food processing, and more. They provide exceptional performance with top forklift brands, such as Hyundai, Yale, Hyster, TCM, Linde, and Doosan.

-

Hyundai

-

Yale

-

Hyster

-

TCM

-

Linde

-

Doosan

Ultimate solution for lithium-ion forklift batteries

Our electric forklift batteries have broad applications in warehouse and logistics centers, manufacturing factories, ports and shipping terminals, cold storage and food processing, and more. They provide exceptional performance with top forklift brands, such as Hyundai, Yale, Hyster, TCM, Linde, and Doosan.

-

Hyundai

-

Yale

-

Hyster

-

TCM

-

Linde

-

Doosan

Discover the perfect fit for Your forklifts

Our cells cover the most forklift ranges, including 24 volts, 36 volts, 48 volts, 80 volts, and max. 350 volts. Whether you are looking for light-capacity solutions for small-size warehouses or heavy-load systems for large-scale ports, we are your final destination for ordering forklift batteries.ROYPOW, Your Reliable Supplier for Forklift Batteries

-

Robust R&D Foundation

Supported by a professional expert team, our company advances forklift power sources to lithium. We are committed to delivering more cost-efficient, safer, and sustainable battery solutions, with significant achievements such as intelligent BMS and remote control.

-

On-Time Delivery

With years of dedication to forklift batteries, we have integrated and optimized our shipping systems, ensuring prompt delivery for every client.

-

Customization Service

ROYPOW offers a comprehensive range of customized options for our forklift truck batteries, tailored to meet the diverse demands of our customers.

-

Thoughtful Customer Service

As a global-targeted brand, we have found subsidiaries across Asia, Europe, Africa, North America, and Oceania. With a worldwide layout strategy, we bring you fast, reliable, and localized support.

Product Case

-

1. When should I charge for forklift battery?

+When the battery level drops below 10%, our forklift battery will alert to prompt charging. Please follow the correct practices to recharge it.

-

2. Who can charge and change batteries for electric forklifts?

+Only well-trained and experienced personnel are allowed to charge and change forklift batteries. Improper handling without adequate training or instructions may lead to battery damage or other potential hazards.

-

3. How long does it take to charge a forklift battery?

+Charging time may vary depending on several factors, such as the battery type, battery capacity, the amperage of the charger, and the remaining capacity. Typically, it takes 1 to 2 hours to charge a forklift truck battery from ROYPOW.

-

4. How long do forklift batteries last?

+ROYPOW forklift batteries feature a service life of up to 10 years and a cycle life of over 3,500 times. Our batteries may have an extended life cycle with proper care and maintenance.

-

5. How much sulfuric acid is in a forklift battery?

+Typically, a lead-acid forklift battery contains approximately 20% sulfuric acid by weight.

-

6. What steps should I take before charging a forklift battery?

+First, turn off the forklift and disconnect the battery. Inspect the charger, input cable, output cable, and output socket.

Second, ensure that the AC input terminal and DC output terminal are securely and correctly connected. Check for any loose connections. Verify whether the air switch is disconnected. Toggle the air switch up and turn on the charger. Charging will automatically start at this point and stop once the forklift battery is fully charged.

-

7. How much does a forklift battery weigh?

+There are a variety of sizes for forklift batteries. A ROYPOW 24-volt forklift battery that is 1,120 amp-hours forklift can weigh more than 9,000 lbs. Before installing a new or different forklift battery, check both the forklift nameplate and battery service weight to make sure that the proper weight battery is being used. A forklift battery of the wrong weight can change the center of gravity and cause equipment to upset.

-

8. When should water be added to a forklift battery?

+All ROYPOW forklift batteries are lithium-ion batteries instead of lead-acid batteries, eliminating the need for water filling. For traditional lead-acid batteries, the ideal time to add water is after the battery has been fully charged since the water level rises during charging, and filling water before charging could lead to overflow.

-

9. What is the IP rating of ROYPOW batteries?

+Standard battery: IP65

-

10. How can I check the residual capacity of the battery after 1–2 years?

+Via the forklift battery display or the ROYPOW app (connected via 4G module).

-

11. Are ROYPOW chargers multi-voltage compatible?

+Yes, our chargers support global voltage platforms (e.g., 36V/48V/80V). Note: 24V batteries use the vehicle’s onboard charger.

-

12. Can ROYPOW batteries be installed in AWP (e.g., Haulotte HA 15 IP)?

+Yes, but we need details like voltage, capacity, weight, dimensions, and discharge plug model for assessment.

-

13. Are ROYPOW batteries compatible with Heli or other forklift brands?

+Yes, they are suitable for all forklift brands.

-

14. Can batteries be ordered without counterweights?

+Yes, ROYPOW lithium forklift batteries can be customized without counterweight blocks.

-

15. Can ROYPOW chargers charge non-ROYPOW lithium batteries?

+Yes, they are compatible with most lithium battery brands.

-

16. What maintenance is required for lithium batteries?

+Fully charge/discharge every 6 months to balance cells. No regular watering or equalization like lead-acid batteries.

-

17. What happens to batteries after 5 years? Does ROYPOW collect them?

+Yes! We offer recycling programs with costs covered by ROYPOW, though policies vary by market.

-

18. Do ROYPOW batteries have telemetry systems for monitoring? What is the input voltage for ROYPOW chargers?

+No, ROYPOW lithium batteries and chargers are designed for safe indoor use without ventilation requirements. ROYPOW battery chargers are compatible with global voltage standards (specifics available upon request).

-

19. What are the advantages of switching from lead-acid to lithium when using forklift truck batteries?

+Lithium-ion forklift truck batteries deliver higher energy density and more stable power output, reducing downtime associated with watering, equalization, and swapping. They are maintenance-free, more compact and often lighter than equivalent lead-acid batteries, enabling longer operational hours, faster charging, and safer, leak-free operation.

-

20. Can a lithium electric forklift battery from one brand be used as a retrofit in a different brand’s forklift?

+Yes. Many electric forklift battery systems (especially from reputable forklift battery manufacturers) are designed to meet common standards (voltage, size, and connection type). As long as you match the voltage, dimensions, and output plug to your forklift’s original specification, a lithium battery should integrate without requiring major modifications.

-

21. Are industrial forklift batteries, like those for heavy-duty warehouse or port use, available in lithium versions, and what should I check when selecting them?

+Yes, many industrial forklift batteries are now offered in lithium versions suitable for heavy-duty applications such as warehouses, shipping terminals, cold storage, and manufacturing. When selecting, make sure to verify the required voltage, capacity (Ah or kWh), compatibility with your lift truck’s make/model, battery weight (to avoid upsetting the center of gravity), and whether the BMS supports multi-shift, high-duty cycles.

-

22. What should I expect when choosing a new fork truck battery in terms of service life and total cost of ownership compared to legacy lead-acid batteries?

+A high-quality lithium fork truck battery typically offers significantly longer service life, often 8–10 years or more, compared to lead-acid batteries. Because lithium batteries rarely require maintenance (no watering, no acid handling) and support fast recharging and multi-shift operations, the total cost of ownership (labor, downtime, maintenance, replacement) tends to be lower over the battery’s lifetime.

-

23. How many cycles should an electric forklift battery from modern forklift battery manufacturers be expected to deliver, and what factors affect this?

+Many of the newer lithium-ion electric forklift batteries from top manufacturers are rated for thousands of cycles (often 3,000+ to 4,000+), assuming proper use and charging. Factors that affect cycle life include depth of discharge, charge/discharge rate, ambient temperature, maintenance practices (e.g., keeping the battery within recommended temperature/voltage ranges), and load profile (how heavily the forklift is used on each shift).

-

24. If I operate a fleet of electric fork truck batteries, what fleet-management benefits might lithium batteries offer over conventional options?

+For a fleet, lithium electric fork truck batteries offer consistent voltage and power output across shifts, reduced downtime (thanks to fast charging and no battery swapping), lower maintenance overhead (no watering or acid-related maintenance), and easier battery asset management (with built-in BMS, remote diagnostics, and often tools for monitoring battery health). This can increase uptime, reduce labor cost, and improve overall operational efficiency.

-

25. What is the difference between forklift truck batteries and traditional industrial battery packs?

+Forklift truck batteries are specifically engineered to handle frequent starts, stops, heavy lifting, and multi-shift operations. Unlike general industrial battery packs, forklift truck batteries must deliver high current output, vibration resistance, thermal protection, and compatibility with counterbalance requirements. Lithium forklift truck batteries further enhance performance with faster charging and zero maintenance.

-

26. How do I select the correct fork truck battery for my specific forklift model?

+To select the right fork truck battery, you must match the voltage (e.g., 24V, 36V, 48V, 80V), physical battery compartment dimensions, connector type, required capacity (Ah or kWh), and counterweight specifications. A professional forklift battery manufacturer can help tailor the exact configuration for your brand and model.

-

27. What factors affect the performance of an electric forklift battery in daily warehouse operations?

+Electric forklift battery performance is affected by load weight, operating temperature, shift length, charging habits, and equipment efficiency. Poor charging practices and extreme temperatures can reduce usable capacity. Advanced lithium electric forklift battery systems automatically regulate these variables through built-in battery management systems (BMS).

-

28. Are electric fork truck batteries safe to use in cold storage and freezer environments?

+Yes, many electric fork truck batteries are specially designed for cold storage environments. Industrial lithium batteries can operate in sub-zero temperatures with integrated self-heating technology, corrosion-resistant enclosures, and temperature-controlled BMS systems to maintain full charging capability in freezer warehouses.

-

29. What industries rely most on industrial forklift batteries today?

+Industrial forklift batteries are essential across logistics, manufacturing, ports, food processing, cold storage, aerospace, pharmaceuticals, and automotive production. Any operation that depends on continuous material movement benefits from high-performance industrial forklift battery systems with fast charging and long duty cycles.

-

30. How does fast charging impact electric forklift battery longevity?

+With lead-acid systems, fast charging often shortens battery life. However, lithium electric forklift batteries are engineered to handle high charging currents safely. Controlled fast charging actually improves uptime without damaging the battery, allowing opportunity charging during short breaks or shift changes.

-

31. What certifications should I look for when evaluating forklift battery manufacturers?

+Reliable forklift battery manufacturers should offer products certified to UL, CE, UN38.3, and ISO standards. These certifications confirm compliance with electrical safety, transportation safety, manufacturing quality systems, and international performance regulations, especially critical for industrial forklift battery deployments.

-

32. Can a single electric forklift battery support multi-shift warehouse operations?

+Yes. Unlike lead-acid batteries that require full discharge and long cool-down periods, lithium electric forklift batteries allow opportunity charging. One battery can power a forklift continuously across multiple shifts with short charging sessions during breaks, eliminating the need for battery swapping rooms.

-

33. What maintenance is required for modern electric fork truck batteries?

+Modern lithium electric fork truck batteries require no watering, no acid checks, no equalization charging, and no corrosion cleaning. Routine maintenance is limited to basic inspections of connectors and software diagnostics, reducing labor costs and safety risks dramatically compared to lead-acid systems.

-

34. How do forklift battery manufacturers design batteries for fleet-level management?

+Advanced forklift battery manufacturers integrate smart BMS platforms, CAN communication protocols, cloud monitoring, and remote diagnostics into their industrial battery systems. This allows fleet managers to track charge cycles, battery health, temperature, uptime, and predictive maintenance across hundreds of forklifts in real time.

Contact Us

Please fill in the form. Our sales will contact you as soon as possible.

Tips: For after-sales inquiry please submit your information here.

Tips: For after-sales inquiry please submit your information here.

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur